The Electron Microscopy Unit of the University of Ioannina is located at the new Building basement of the Department of Materials Science Engineering and it is consisting from the following equipment (primary and secondary):

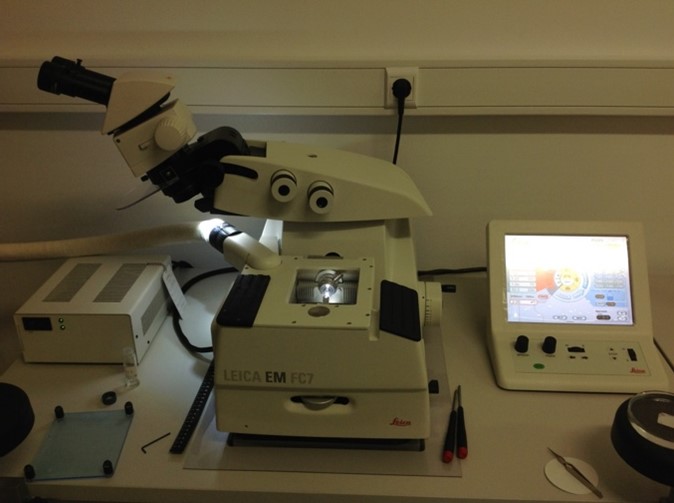

Two (2) Ultra-Cryomicrotomes for thin sections used in TEM (1 through donation from DMSE/MIT and Professor E. L. Thomas) and a new one as of May 2012 from Leica Instruments through competitive funding, Leica EM UC7 Ultramicrotome)

With these instruments (Figure 1) the ability to obtain thin sections from bulk films as low as 5 nm is possible. They are used in ambient conditions (environmental microtoming) and at cryogenic conditions as low as -1600C (ultra-cryomicrotoming).

The usual requirements for the obtained thin sections to be observed by TEM is for their thickness to range from 20 nm up to 70 nm. These thickness values depend on the specimen, the staining requirements, the accelerating voltage at which they will observed and their sensitivity (thermal, degradation/decomposition, cross-linking) under the electron beam exposure.

Glass knives and diamond knives are used for the collection of the sections. The diamond knives are differentiated according to the conditions used (ambient or cryogenic). Deviations and deformation of the sections due to static electricity (especially during ultra-cryomicrotoming conditions) are substantial. In total there are four diamond knives, two for ultra-cryomicrotoming and two for environmental microtoming.

Many different preparation protocols can be used for obtaining the desired thin sections in both conditions and the grids used for deposition of the sections are variable according to demand, type of sample and imaging requirements.

|

|

|

Figure 1. Ultra-Cryomicrotomes. Left image: The new as of May 2012 from Leica Instruments, model: Leica EM UC7 Ultramicrotome, right image: The older microtome through donation from DMSE/MIT, model: Reichert- Jung FC 4E cryo-ultramicrotome.

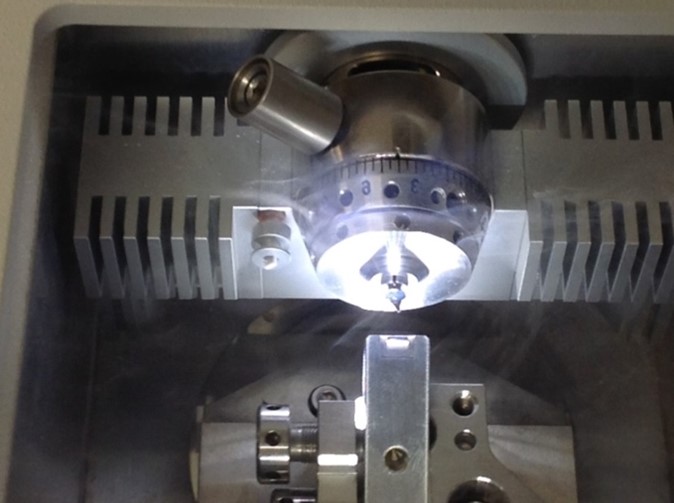

In Figure 2 additional images are shown for the working space of the ultra-cryomicrotome Leica EM UC7 Ultramicrotome under cryogenic conditions. Figure 2 (top image) indicates the area where specimen and knives (glass and diamond) are located as well as the control panel is observed. Figure 2 (center image) the area of the specimen and the diamond knife is specified under cryogenic conditions (ultra-cryomicrotoming) and magnified further in Figure 2 (lower image) for better observation.

|

|

|

Figure 2. Top image: area where specimen and knives (glass and diamond) are located as well as the control panel, center image: area of the specimen and the diamond knife, bottom image: magnification of specimen and diamond knife for better observation.

High-Resolution Transmission Electron Microscopy (HR-TEM) from JEOL (JEM 2100HR, LaB6 filament)

The high-resolution electron microscope of the Electron Microscopy Unit of the University of Ioannina is shown in Figure 3.

Figure 3. High Resolution Transmission Electron Microscope (HRΤΕΜ), model JEM 2100HR (JEOL Ltd).

General Information

The transmission electron microscope consists of two basic systems: the illumination system and the image projection system.

The illumination system comprises the gun and the condenser lenses and its role is to take the electrons from the source and transfer them to the specimen. The electron gun is normally fitted with a tungsten filament cathode as the electron source. The electron beam is accelerated by an anode typically at 100-200 keV, while advanced TEMs can reach up to 1MeV which provides better examination of thicker specimens.

The image projection system comprises from the objective lens, the intermediate lens, the diffraction lens, the projection lens, the viewing luminous screen for the observation of the specimen and the photographic camera. The first and most important magnification of the sample is performed by the objective lens where the rest of the lenses create the final magnification.

The major features are dependent on the system, the goniometer and the mounting. More specifically:

System: By creating the status display of the basic unit and operation screen using JEOL’s graphical user interface based on MS Windows software, this system is easy to operate, even for beginners. In addition, by providing powerful external control functions, it lets you program a series of operations and facilitates useful collaboration with other peripheral equipments.

Goniometer: By not only drastically enhancing the after-drift and tilting performances of the stage, but also completely computerizing the stage-control system, the operation environment of the stage has been substantially improved over any conventional instrument. Moreover, piezoelectric drive mechanisms make sub-nanometer stage movement possible.

Mounting: The mounting not only enhances the vibration- and earthquake-resistance performance by supporting the column nearest the center of gravity of the electron microscope, but also it affords you to select the best mounting according to the floor vibration in the installation room by increasing the choice of mountings.

Specifications of the TEM instrument

The JEM-2100HR is equipped with EDS, STEM mode, EELS and more specifically:

The general specifications of the instrument are (according to basic parts as given below):

|

Condenser Lens (CL) |

|

|

Lens system: |

(for high-resolution system, HR) |

|

Variable apertures: |

Click-stop aperture selection |

|

Stigmator: |

Zoom, electromagnetic with centering mechanism |

|

Axis alignment: |

Shift and tilt, electromagnetic balanced double deflector |

|

Quick beam selector: |

(for high-resolution system, HR) |

|

α-selector: |

(for high-resolution system, HR) |

|

Dark-field image Beam tilt: |

UHR, HR, HT, CR |

|

Specimen Chamber |

|

|

Specimen stage: |

Side-entry eucentric goniometer with Z-movement fine control |

|

Specimen exchange: |

Automatic airlock |

|

Anti-contamination device: |

Built-in |

|

Specimen holder: |

Common specimen holder with quick-change retainer |

|

Specimen movements: |

X, Y and Z directions, and X-tilt (motor driven) |

|

Image fine shift: |

±2 mm (X and Y) (TEM mode) |

| Objective Lens | |

| Lens system | Two-stage objective lens: Objective lens Objective Mini lens Wobbler built-in |

| Variable aperture: | for high-resolution system, HR)

Click-stop aperture selection |

| Stigmator: | Electromagnetic with centering |

| Focusing: | Digital coarse/fine controls Focus zoom system Image wobbler built-in |

| Intermediate Lens (IL) and Projector Lens (PL) | |

| Lens system: | Four-stage lens system: 1st IL 2nd IL 3rd IL PL Distortion-free Rotation-free |

| Selected-area apertures: | Click-stop aperture selection Metal bellows type aperture rod Four-disc-apertures (10-20-50-100 mm diameter) foil |

| Axis alignment: | Mechanical and electromagnetic |

| Stigmator: | Electromagnetic with centering |

| Shutter: | Built into the PL |

| Air-lock valve: | Built-in |

| Diffraction Chamber | |

| Port for optional equipment: | Provided as standard Attachment installed to the port is optional. |

| Viewing Chamber | |

| Viewing windows: | 250´170 mm at front |

| Fluorescent screens Observation: |

160 mm diameter |

| Focusing: | 25 mm diameter |

| Binocular microscope: | x 10 |

| Beam stopper: | Available as an option |

| Photographing System | |

| Camera: | Sheet-film magazine type |

| Film sizes: | 90´65 mm (for Europe) |

| Number of films: | 50/magazine |

| Film feeding: | Automatic (one-by-one or successive feeding selectable) Multiple-exposure available |

| Exposure: | Fully automatic or manual |

| Exposure meter: | Electron beam detection Averaging or spot measurement |

| Metering range: | 5 x 10-13 to 5 x 10-10 A/cm2 |

| Shutter speed: | 0.1 to 90 s, and B (bulb) |

| Unexposed-film count: | Digitally displayed |

| Data for recording on film: | Film number Operator code Magnification or camera length Micron bar Accelerating voltage Text |

| Photographing history list: | Data on 50 most recently exposed films can be stored |

| Film exchange: | Automatic airlock and lightproof magazines used. Number of loading magazines: Send magazines: 1 Receive magazines: 1 Number included with JEM-2100: Send magazines: 2 Receive magazines: 2 |

| Film desiccator (optional): | Separately placed |

| Vacuum System | |

| Evacuation: | Perfectly differential pumping |

| Control: | Fully automatic sequential control Evacuation system monitor built-in |

|

Vacuum pumps Gun and specimen chambers: |

150 L/s sputter ion pump (SIP) 1 |

|

Viewing and camera chambers Roughing pump: |

420 L/s oil diffusion pump (DP) 1 100 L/min oil rotary pump (RP) 1 |

| Vacuum gauges: | Two Pirani gauges and one Penning gauge |

| Pressure: | 2 x 10-5 Pa or less |

| Automatic mild-bakeout function: |

Provided |

| Dry nitrogen gas vent system: | Gas-vent automatic shutoff built-in (Dry nitrogen gas and pressure regulator are user-provided.) |

| Operation System | |

| Operation panel: | For normal observation operations |

| Operation screen: | Windows based |

| Windows is a trademark of Microsoft Corporation. | |

| Monitor: | LCD |

| Computer for operation: | Personal computer (PC) |

| Safety Devices | |

| Safety devices: | Devices to protect against power and water failures are provided. |

| Self-diagnostic functions: | When the JEM-2100 shuts down due to the causes shown below, the evacuation system monitor indicates the causes: Pneumatic pressure abnormality RP belt break DP heater burnout Cooling water abnormality Pirani gauge filament break Reservoir tank pressure abnormality |

The main system configuration (JEM-2100HR) which is functional in the Electron Microscopy Unit of the University of Ioannina, since it is High-resolution is as follows:

EM-21000BU. Electron Microscope Basic Unit

EM-20500 CM Lens Unit

EM-20720 High Resolution Polepiece

EM-20080 High Contrast Objective Aperture

EM-23110 SIP Vacuum Pump

EM-27112PCU Computer Unit

EM-27121MON Main Monitor

EM-08010 Air Compressor

Scanning Electron Microscopy-Low Vacuum (SEM-LV) from JEOL (JSM-6510LV, LaB6 filament)

The Scanning Electron Microscopy-Low Vacuum (SEM-LV) of the Electron Microscopy Unit of the University of Ioannina is shown in Figure 4.

Figure 4. Scanning Electron Microscope (SEM).